Progress for 0 ad

Progress for 1 ad

Progress for 2 ad

Progress for 3 ad

Rahel Solomon

Addis Ababa, Ethiopia

From Kaffa, the place that lent its name to the bean, to a quarter of the country’s population – engaged in production, processing, distribution, and exporting the commodity, coffee is undoubtedly a big deal in Ethiopia.

Coffee generates more than 30 percent of the nation’s foreign exchange earnings. In the 2021-2022 period, Ethiopia earned 1.4 billion dollars exporting 300,000 tons of coffee, a record high in the nation’s export history.

While this is something widely celebrated, discussions about the massive amounts of waste coffee production leaves behind are not heard quite often.

Ethiopia’s coffee waste figures are actually comparable to the amount of coffee the country exports. A 2017 study stated that Ethiopia disposes of 192,000 tons of coffee husk annually.

It’s this problem that Husky Energies & Technology, a renewable energy startup, has adopted as its mission to tackle by turning coffee waste into a source of energy, solving energy poverty and indoor pollution along the way.

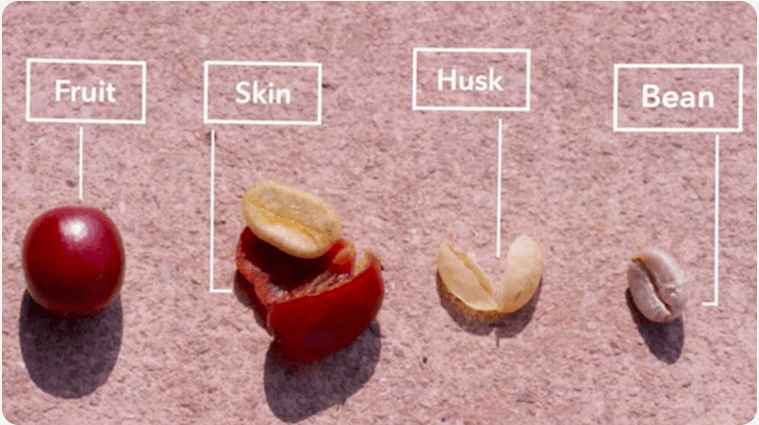

The processing of coffee generates significant amounts of agricultural waste, ranging from 30pc to 50pc of the weight of the total coffee produced.

The husk is the dried skin of the bean and is the major solid residue from the processing of coffee. The husk falls off and is usually left behind, and its adequate disposal constitutes a major environmental problem.

Coffee husk contains some amounts of caffeine and tannins, which makes it toxic to be fed to animals. Globally, one of the uses for coffee husks is to make them into fertilizer.

But in Ethiopia, timing has made their use for fertilizers impossible. There is a mismatch between the months farmers need fertilizer, the beginning of the rainy season, and when the husk is disposed of, which is in winter. Since the husk is not immediately used, it sits and decays.

Founded by two innovative and passionate mechanical engineers, Hoheyat Berhanu and Yohannes Wasihun, who graduated from Addis Ababa University last year, Husky Energies & Technology’s solution to the waste problem was the topic of their bachelor’s degree thesis.

“As part of our internship, both of us were working at Green Bean Manufacturing,” said Hoheyat.

Green Bean is a startup working on innovative solutions that maximize the yield and quality of major agricultural products, such as coffee.

As part of their duties, Hoheyat and Yohannes were responsible for training farmers on using Green Bean’s coffee dryer machines.

It was a tea break during a training session; the duo were asking farmers from the Yirgachefe area what other problems they faced in their coffee production.

The friends learn that disposing of coffee husks is a huge problem for farmers, causing many hazards. The husk takes large hectares of land and sits decaying for months, polluting the area before it’s finally burnt by the farmers, adding another environmental damage to its name.

After hearing about the problem, the friends further researched the issue, learning it’s a real and pressing problem globally. They also found that coffee husk could be turned into an energy source, a practice common in other countries.

Hoheyat and Yohannes decided to deal with the topic in their thesis, with the paper covering the mechanics behind the conversion.

Through their thesis, they designed machines that turn coffee husks into biofuels called pellets and briquettes. The biofuels are made from compressed coffee waste and could be carbonized.

The carbonized briquettes and pellets undergo carbonization, including a heated drying step to get rid of the water and make them strong enough to be used in the same burning capacity as charcoal. Meanwhile, the non-carbonized briquettes are produced from waste materials in their natural form.

Husky’s biofuel energy content is both comparable to charcoal and wood. Charcoal has an average energy content of around 27 MJ/kg. In comparison, firewood has an average energy content of 18 MJ/kg. Meanwhile, Husky’s uncarbonized biofuels produce 24 MJ/kg and carbonized ones 27 MJ/kg.

Besides the energy factor, the advantage of Husky’s product is that it reduces smoke by 90 percent in its production and usage, making it environmentally safe.

Charcoal is a major source of energy for cooking and heating both in Ethiopia and the capital. A study conducted in 2010 found that 68,886 tons of charcoal per year are supplied to Addis Ababa.

This is equivalent to about 899,818 trees being cut down for this supply, releasing about 125,717 ― 167,623 tons of carbon into the atmosphere.

On the other hand, indoor pollution kills around 4 million people worldwide, and 50,000 people die in Ethiopia.

While the theoretical aspects were covered, the partners also worked on turning the idea into a business.

Their business plan involved selling biofuels as a primary product while selling gasifier stoves, fast-food pushcarts, and biomass electric generators that are run by the biofuels as their secondary products to create a sustainable environment as well as a market chain for their main product.

With funds secured from STEMpower, a nonprofit organization and prize money from winning the 2021 Bruh Business Idea Competition, Husky built the prototypes. The machines can produce 20 kg of coffee waste pellets per hour.

Global biofuel production is rising as the world is slowly moving towards renewable energy. In Ethiopia, there has been scattered biofuel production and the sector remains largely untapped and at an infant stage.

Husky, as of now, is building new machines that have the capacity to produce 100 kg of biofuel per hour. With ongoing work on securing a workshop in the capital, the startup plans to start producing 1.6 tons of biofuel per day in the next six months. As coffee processing plants exist in Addis Ababa, they also plan to source their inputs from the capital.

Husky plans to sell 1 kilogram of their biofuels for 15 birr, which is cheaper than charcoal in the market, which goes for around 21 birr.

Besides consumer use, Husky targets hotels and restaurants as clients as these businesses largely use charcoal in their food preparation.

Husky’s midterm goal is the production of 5 tons per day in 2-3 years. For now, they say they have four expressions of interest from companies for their biofuels. They also say they are in talks with exporters. Meanwhile, they are looking for partners and investors that could help them scale.

👏

😂

❤️

😲

😠

Rahel Solomon

Your Email Address Will Not Be Published. Required Fields Are Marked *